In a technological design process, we must rely on the manufacturing process sheet and the assembly sheet (or process sheet) to build the prototype.

The manufacturing process sheet is a document which describes, in detail, all the technical information necessary for manufacturing one or more parts of a technical object.

When a person makes a unique piece, they can develop a plan that is more or less accurate and that will allow them to obtain the desired final object. However, if they later try to reproduce this object, there could be slight differences in the items.

To mass produce an object, that is to say to produce a large number of identical objects, it is important to follow a method describing each of the steps required for manufacturing it. This is called a manufacturing process sheet.

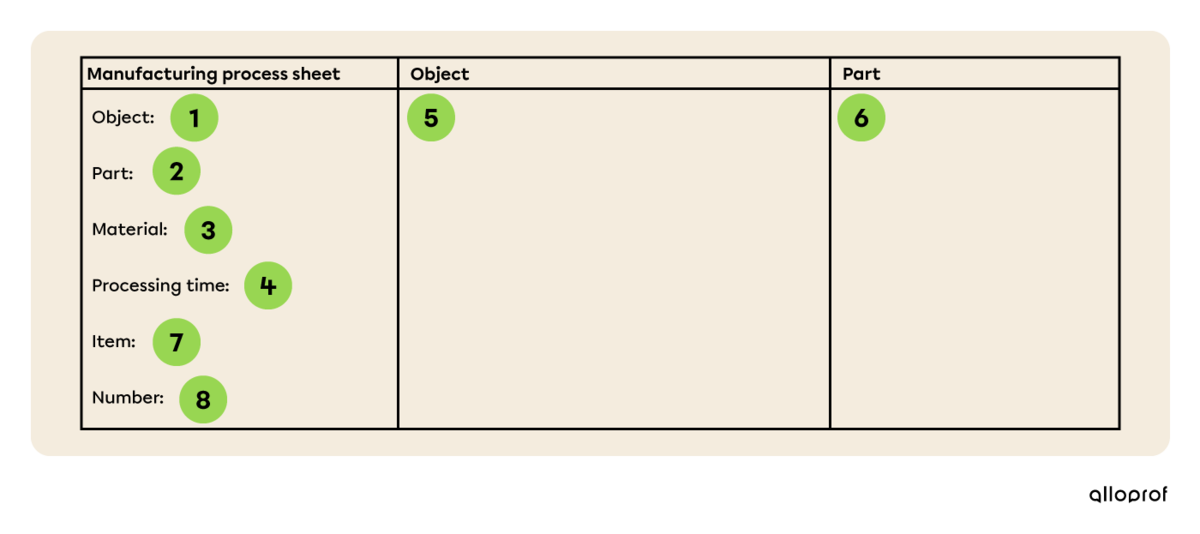

The manufacturing process sheet is presented in the form of a table. The header contains the following information:

- the name of the object;

- the name of the part to build;

- the material to be used;

- the processing time;

- the drawing of the complete object with reference marks (numbers) for each part;

- the drawing of the part to be manufactured;

- the item, or the name of the part, to be produced linked to the drawing of the full object;

- the number of identical parts to be manufactured.

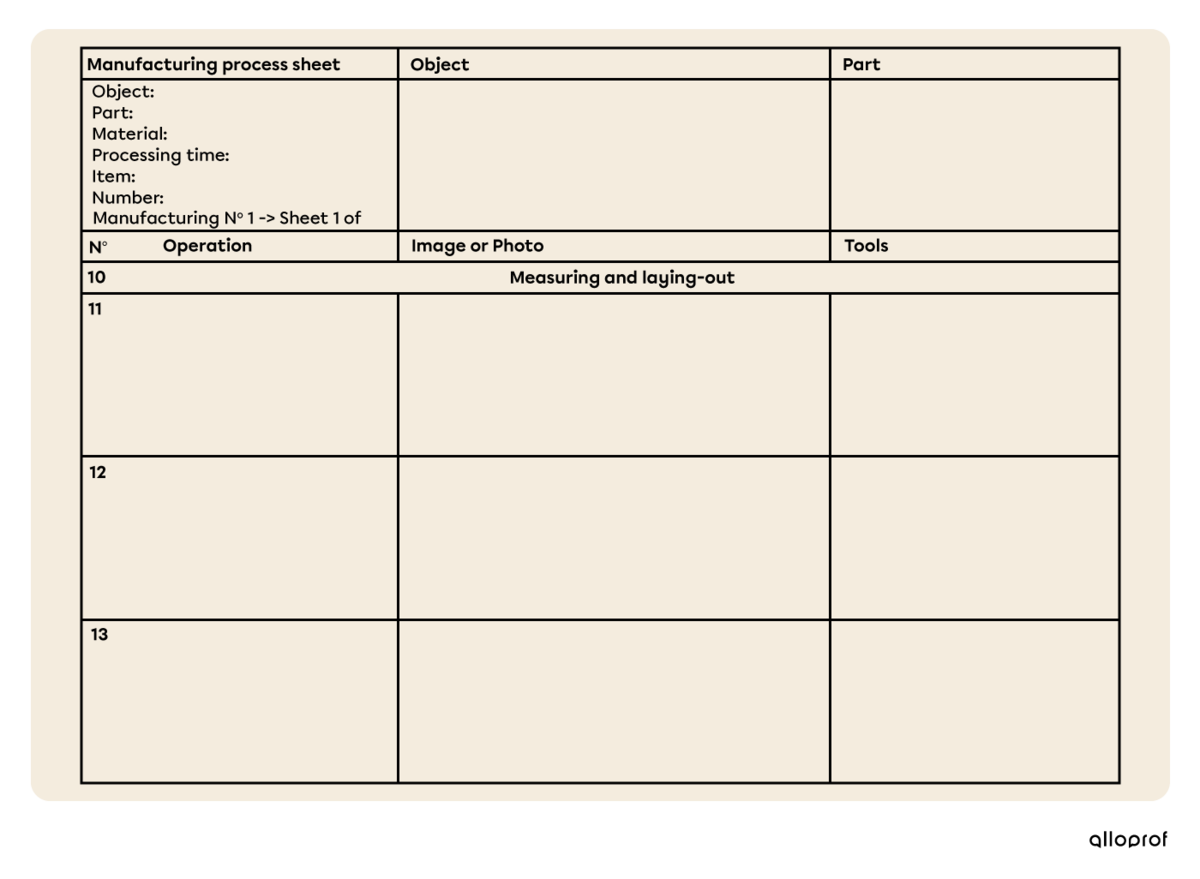

The manufacture of a technical object consists of 3 phases:

The steps of these 3 phases are numbered in a different way in the manufacturing process sheet. The measuring and laying out steps are numbered 11 to 19, machining steps are numbered 21 to 29, and the finishing steps are numbered 31 to 39.

Once all the parts of an object have been manufactured using manufacturing process sheets, they are assembled by following an assembly sheet, also called an assembly line.

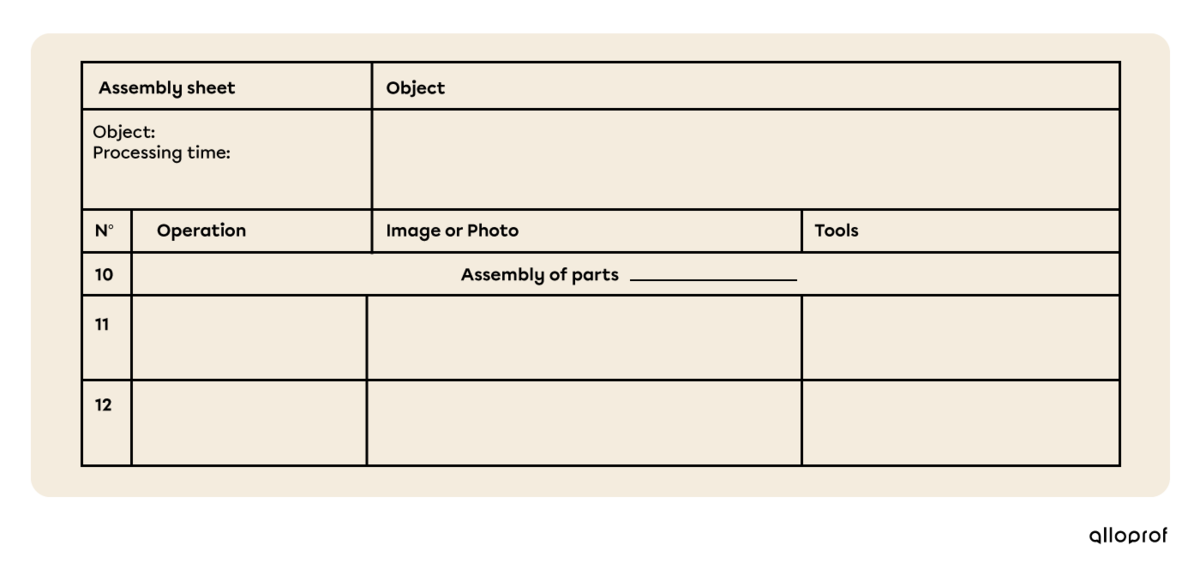

The assembly sheet is a document that describes the assembly order and techniques as well as the linking components to use to join all the parts of the object.

An object’s assembly can be done in several phases. Each phase represents the assembly of 2 or more parts. The number of phases varies depending on the item to be crafted.

The operations of these phases follow a numbering similar to that of the production plan. The operations of the 1st phase are numbered according to numbers 11 to 19, those of the 2nd phase according to numbers 21-29 and so on, in order of implementation.

Like the manufacturing process sheet, the assembly sheet is presented in the form of a table.