When being used, the materials of a technical object can undergo constraints causing deformations. The materials are also likely to deteriorate. Therefore, special attention must be given to the choice of materials depending on the purpose of the technical object involved.

-

A metal is a lustrous (or shiny) material that is generally a good conductor of heat and electricity.

-

A pure metal is an element, because it contains only one type of atom.

In nature, metals are rarely found in their pure state. More often, they are mixed with other substances in ores in the Earth's crust. Once the ores are mined, they can undergo various processes to separate the different substances in the ore.

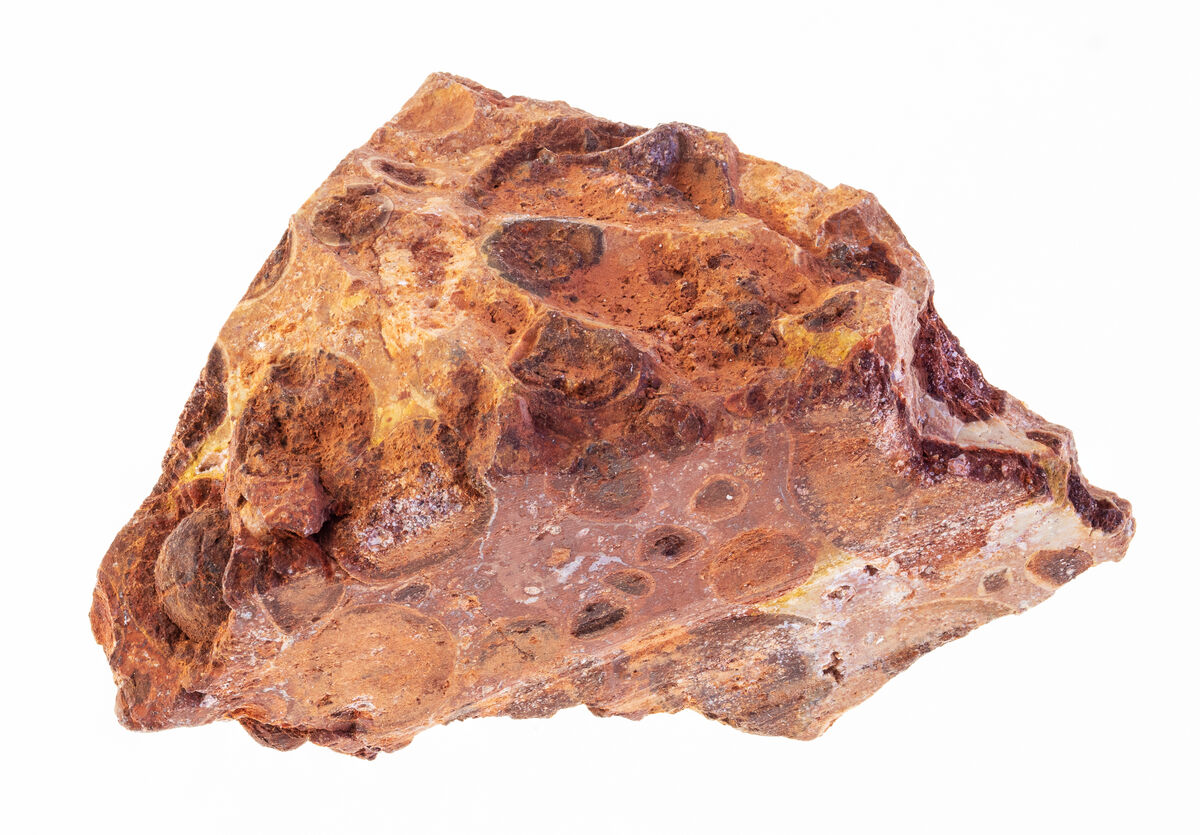

Bauxite is an ore that contains iron (|\text{Fe}|), oxygen (|\text{O}|), a lot of aluminum (|\text{Al}|), and several other elements. Various processes can be used to extract metals from bauxite, including aluminum (|\text{Al}|).

KrimKate, Shutterstock.com

Apart from ores, metals are also found in meteorites.

Ferrous meteorites are mainly composed of iron, but also contain nickel and other metals. This type of meteorite was widely used during prehistoric times as the primary source of iron. It was used to make jewellery and tools.

Olin Feuerbacher, Shutterstock.com

Over 90 different metals can be found in the periodic table of elements. Metals generally have a lustrous (or shiny) appearance and conduct heat, as well as electricity. Since the metals have a wide variety of properties, only some of them are used frequently to manufacture technical objects.

The following tables show some of the most commonly used metals along with their mechanical, physical and chemical properties (called physicochemical). Metals are more likely to be used in the form of an alloy than in the form of an element (in their pure state).

Iron is a silvery metal. It is the most widely used metal. It is primarily used to create ferrous alloys.

| Main Mechanical and Physicochemical Properties |

|---|

| Ductility, malleability, and susceptibility to corrosion (rusts easily) |

| Examples of Use |

| Cars, building structures, utensils, cables, nails, etc. |

Gray_and, Shutterstock.com

Aluminum is a silvery white metal abundant in nature.

| Main Mechanical and Physicochemical Properties |

|---|

| Malleability, ductility, flexibility, lightness, good conductivity, and resistance to corrosion |

| Examples of Use |

| Boats, electrical wires, cans, doors, windows, etc. |

Nils Z, Shutterstock.com

In the previous table, aluminum is described as “light.” When we talk about lightness, we are not referring to the mass, but rather to the density. Therefore, when we say that aluminum is light, we mean it is not very dense; it has a low density.

Likewise, when we say that copper is “heavy” in the following table, we mean it is dense; it has a high density.

Copper is a reddish-brown metal.

| Main Mechanical and Physicochemical Properties |

|---|

| Ductility, malleability, heaviness, high electrical conductivity, thermal conductivity, and susceptibility to corrosion (turns green) |

| Examples of Use |

| Electrical wires, musical instruments, statues, church domes, etc. |

Adwo, Shutterstock.com

Zinc is a very lustrous silvery white metal.

| Main Mechanical and Physicochemical Properties |

|---|

| Hardness, rigidity, malleability, and resistance to corrosion |

| Examples of Use |

| Electrical wires, roof gutters, fences, corrosion-resistant coating, etc. |

Foto_grafica, Shutterstock.com

Magnesium is a silvery white metal.

| Main Mechanical and Physicochemical Properties |

|---|

| Malleability, ductility, lightness, and flammability |

| Examples of Use |

| Fireworks, flares, car rims, etc. |

Evannovostro, Shutterstock.com

Gold is a golden (or yellow) metal.

| Main Mechanical and Physicochemical Properties |

|---|

| Ductility, malleability, heaviness, and resistance to corrosion |

| Examples of Use |

| Electrical connectors, old coins, works of art, etc. |

SOMMAI, Shutterstock.com

Silver is a very lustrous silvery white metal.

| Main Mechanical and Physicochemical Properties |

|---|

| Malleability, ductility, high thermal and electrical conductivity |

| Examples of Use |

| Electrical connectors, semiconductors, silverware, etc. |

Vittoria_vittoria, Shutterstock.com

Tin is a silvery white metal.

| Main Mechanical and Physicochemical Properties |

|---|

| Ductility, malleability, and low melting point |

| Examples of Use |

| Welding, cans, utensils, etc. |

Natee Photo, Shutterstock.com

Titanium is a silvery white metal.

| Main Mechanical and Physicochemical Properties |

|---|

| High ductility, lightness, and resistance to corrosion |

| Examples of Use |

| Dental implants, prostheses, aircraft parts, etc. |

Alex Mit, Shutterstock.com

Lead is a bluish grey metal. It has been used sparingly since the discovery of its toxicity.

| Main Mechanical and Physicochemical Properties |

|---|

| Malleability, ductility, heaviness, and resistance to corrosion |

| Examples of U |

| X-ray protective clothing, soundproofing in recording studios, etc. |

Radiography art, Shutterstock.com

An alloy is a solid homogeneous mixture composed of a metal and one or more other substances. The other substances can be metallic or non-metallic.

When developing a technical object, materials are chosen for their specific properties. It is the reason why alloys are often more useful than metals in their pure state. In fact, mixing substances makes it possible to combine their properties. In some ways, metals are customised to obtain an alloy with specific properties to meet our needs. It is possible, for instance, to increase the hardness of a metal, thus improving its resistance to wear while maintaining good malleability.

Alloys are generally classified into two categories: ferrous alloys and non-ferrous alloys.

Alloys and composite materials should not be confused. Alloys are homogeneous mixtures consisting of at least one metal, while composite materials are heterogeneous mixtures.

A ferrous alloy is an alloy with iron as its main component.

Iron is one of the most common elements in the Earth's crust. It is ductile (can be stretched), malleable (can be flattened into sheets), and magnetic. However, iron in its purest form is not resistant to corrosion or wear. By combining it with carbon, its rigidity and hardness can be increased. Depending on the proportions of iron and carbon found in the alloy, its properties will be modified differently.

The most common ferrous alloys include iron and carbon. Nevertheless, iron can be alloyed with other elements like chromium, nickel, and many other elements.

The following tables display several examples of ferrous alloys as well as their properties.

Cast iron is a lustrous white or grey ferrous alloy. It is composed of iron and at least 2% carbon.

| Main Mechanical and Physicochemical Properties |

|---|

| Hardness, brittleness, and heaviness |

| Examples of Use |

| Pans, works of art, pipes, dumbbells, etc. |

Mariyana M, Shutterstock.com

Stainless steel is a ferrous alloy with a metallic grey colour. It is composed of iron, carbon (less than 1.5%), chromium, and tin.

| Main Mechanical and Physicochemical Properties |

|---|

| Hardness, rigidity, and resistance to corrosion |

| Examples of Use |

| Kitchen utensils, aircraft parts, etc. |

Phive, Shutterstock.com

Mild, or low carbon, steel is a ferrous alloy with a metallic grey colour. It is composed of iron and barely 0.2% carbon.

| Main Mechanical and Physicochemical Properties |

|---|

| Hardness and low resistance to corrosion |

| Examples of Use |

| Chains, sheet metal, angle iron (L-shaped fittings), etc. |

Fedorov Oleksiy, Shutterstock.com

Tinplate is a metallic grey ferrous alloy. It is a thin sheet of low carbon steel coated with a layer of tin on both sides. This type of alloy is widely used for preserving food.

| Main Mechanical and Physicochemical Properties |

|---|

| Ductility and resistance to corrosion |

| Examples of Use |

| Tin cans, cookie tin boxes, tea tins, etc. |

Madiz, Shutterstock.com

Surgical steel is a ferrous alloy with a metallic grey colour. It is composed of iron, chromium, nickel, and molybdenum.

| Main Mechanical and Physicochemical Properties |

|---|

| Hardness, wear resistance and resistance to corrosion |

| Examples of Use |

| Surgical instruments, orthopaedic implants, etc. |

Sakan.p, Shutterstock.com

A non-ferrous alloy is an alloy that does not contain iron. Therefore, the alloy consists of a metal other than iron and one or more other substances.

Non-ferrous alloys have various properties. Most magnetic alloys are, in fact, ferrous alloys, but some non-ferrous alloys can also be magnetic. To find out, a magnet can be used. If the magnet is attracted to the alloy, then the alloy is magnetic.

The following tables show several examples of common non-ferrous alloys and their properties.

Brass is a non-ferrous alloy composed of zinc and copper. Its colour can vary from pink to yellow depending on the proportions of the different metals.

| Main Mechanical and Physicochemical Properties |

|---|

| Ductility, malleability, heaviness, effective conductivity, and resistance to corrosion |

| Examples of Use |

| Decorations, electrical components, musical instruments, etc. |

Stockphoto-graf, Shutterstock.com

Bronze is a non-ferrous alloy composed of copper and tin. Its colour can vary from yellow to brown.

| Main Mechanical and Physicochemical Properties |

|---|

| Hardness, malleability, heaviness, effective conductivity, and resistance to corrosion |

| Examples of Use |

| Works of art, boat propellers, valves and fittings, Olympic medals, etc. |

Africa Studio, Shutterstock.com

Titanium alloy is a non-ferrous alloy composed of titanium, aluminum, and various metals. It has a silvery grey colour.

| Main Mechanical and Physicochemical Properties |

|---|

| High hardness, malleability, lightness, and resistance to corrosion |

| Examples of Use |

| Aircraft parts, bicycle frames, electronic parts, etc. |

Rudy Umans, Shutterstock.com

Samarium-cobalt is a non-ferrous alloy composed of samarium and cobalt. This silver-grey alloy is used specifically for its strong magnetism.

| Main Mechanical and Physicochemical Properties |

|---|

| Very strong magnetism and resistant to corrosion |

| Examples of Use |

| Headphones, electromagnetic pickups on electric guitars, advanced electric motors, etc. |

Optimarc, Shutterstock.com

Heat treatment of alloys is a process that modifies the mechanical properties of an alloy by subjecting it to cycles of heating and cooling.

Here are the three main heat treatments for alloys.

Quenching involves heating an alloy to a very high temperature and then rapidly cooling it using a cold fluid. This process reorganizes the atoms within the alloy, giving it new properties.

Quenching increases hardness, but it also makes the material more brittle and reduces its ductility.

Source: Maksim Safaniuk, Shutterstock.com

Tempering involves heating an alloy that has already been quenched. Tempering must be done at a precise temperature that is lower than the quenching temperature.

Tempering allows the alloy to regain some ductility and resilience while preserving the hardness gained through quenching. The higher the tempering temperature, the more ductile and less hard the alloy will be.

Annealing involves heating an alloy and then letting it cool slowly.

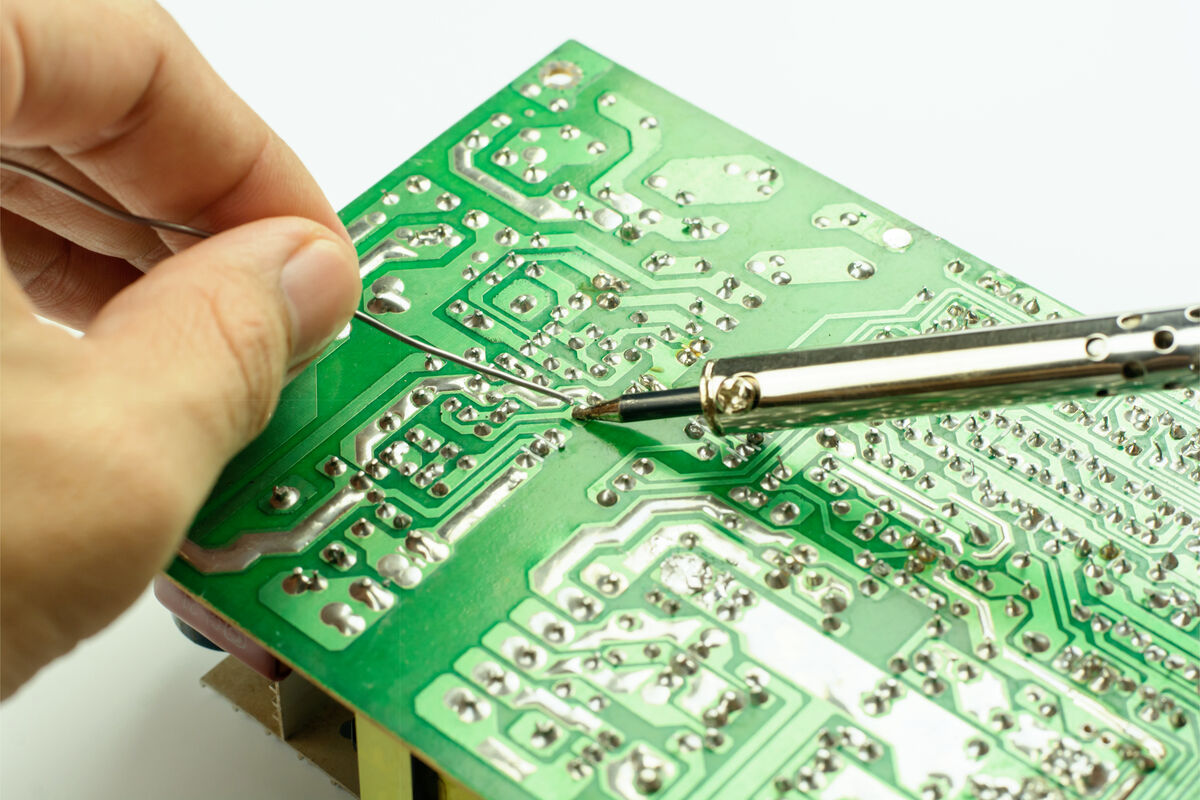

Annealing somewhat reduces the hardness of an alloy. It also helps restore its original properties after it has undergone another heat treatment or been deformed. For example, annealing is used to eliminate traces of welding.

All metals are different, so their properties may vary greatly from one metal to another. However, certain properties are found in several metals. In fact, in terms of mechanical properties, the metals and alloys used to manufacture technical objects are often ductile and malleable (e.g., iron, aluminum, brass, etc.). With regard to physical and chemical properties, they are often lustrous substances, and effective electrical and thermal conductors. As for magnetism, it is particularly noticeable in iron, nickel, cobalt, and some other less common metals.

The tables above show the properties of metals and alloys commonly used to manufacture technical objects.

Changes in a material’s properties caused by its environment are known as degradation. Various protection methods are used to prevent or slow down the degradation of metals and alloys.