A mechanical property is a characteristic property of a material that describes its behaviour when subjected to one or more mechanical constraints.

Knowing the mechanical properties of materials is essential for designing and manufacturing technical objects. In order for a technical object to fulfill its overall function and to withstand the various constraints to which it is subjected, it is important to select the appropriate materials.

The following table displays the main mechanical properties.

| Mechanical property | Description | Examples of materials |

|---|---|---|

| Ductility | Ability to stretch without breaking and retain its new shape | Copper Gold |

| Hardness | Ability to resist penetration and scratches | Steel Porcelain |

| Elasticity | Ability to deform and then return to its original shape | Rubber Polychloroprene |

| Brittleness | Ability to break easily | Glass Porcelain |

| Malleability | Ability to flatten or bend without breaking and retain its new shape | Aluminum Copper |

| Resilience | Ability to withstand shocks | Cast iron Melamine |

| Stiffness | Ability to resist deformation | Reinforced concrete Plywood |

All materials have a limited ability to deform or resist deformation. When too much constraint is applied, the material undergoes permanent deformation or it breaks the material. For example, rubber has good elasticity, but if stretched with too much force, it may break instead of returning to its original shape.

Pour valider ta compréhension à propos des propriétés mécaniques des matériaux de façon interactive, consulte la MiniRécup suivante :

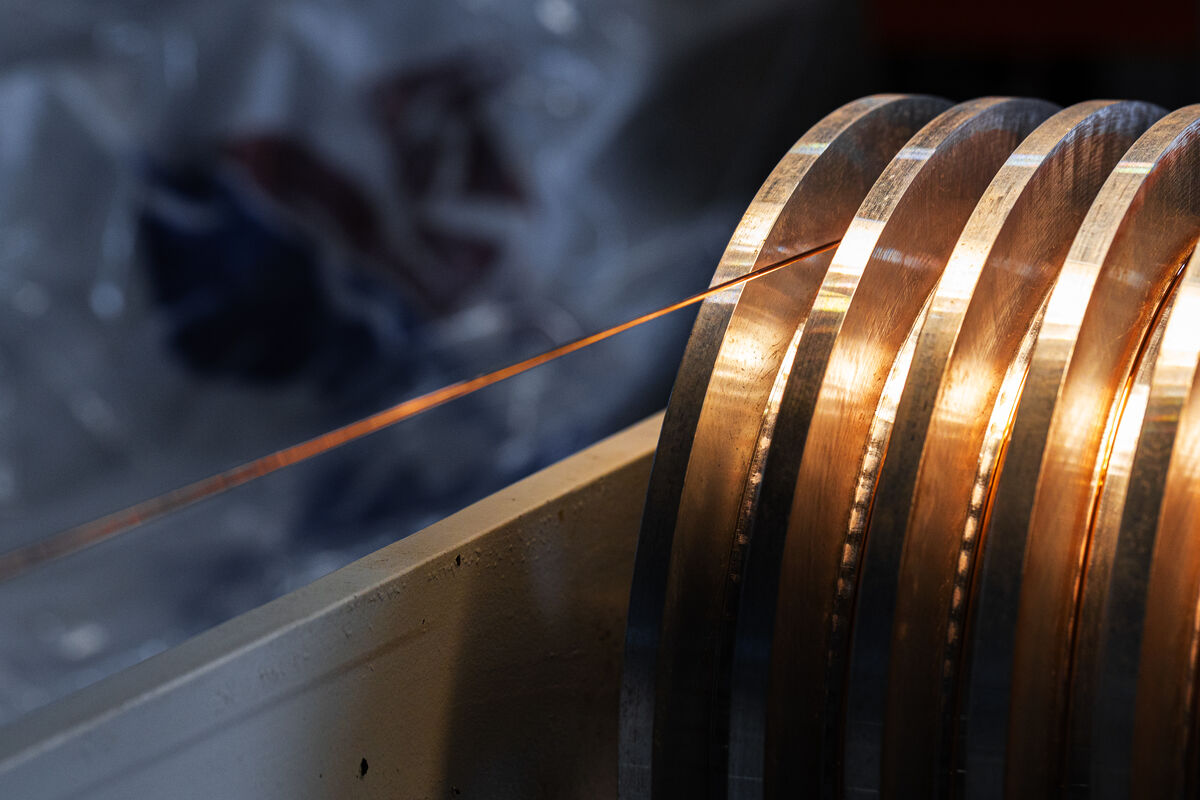

Ductility is the ability of a material to deform, more specifically to stretch, without breaking and to retain its new shape.

Most metals and alloys possess excellent ductility. This is why these materials are frequently selected for the production of wires or cables.

In a factory, a thick copper rod is passed through a pulley system that stretches it into a long thin wire.

FabrikaSimf, Shutterstock.com

Materials such as wood and ceramics are not ductile since they do not stretch. Generally, materials that are ductile are also malleable.

Hardness is the ability of a material to withstand penetration and scratching.

Ceramics, several metals and their alloys, as well as some plastics, have good hardness. These materials are found in abundance in the construction industry as finishing materials, because their surface remains intact over time. The hardness of different woods varies according to their species. For example, maple (a hardwood) is harder than pine (a conifer).

The hardness of porcelain ceramic makes it a durable choice for scratch-avoidant flooring.

sevi gadea, Shutterstock.com

The hardness of materials also makes it possible to choose the appropriate tool in order to make a notch or a cut. In fact, the hardness of the tool used must be greater than that of the material being cut.

Diamond is the hardest natural substance. It can be used to cut pieces of glass. Since diamond is harder than glass, it penetrates the glass and leaves a scratch.

For this reason, there are small pieces of diamond on the blade of a glass cutter.

noprati somchit, Shutterstock.com

The Mohs scale is used to measure the hardness of minerals. It was invented in 1812 by Friedrich Mohs, a German mineralogist. Hardness is rated on a scale from 1 to 10. The scale compares the ability of a mineral to scratch another.

Gypsum can be scratched by fingernails, while calcite can be scratched by a copper coin. This means that calcite is harder than gypsum. Diamond can only be scratched by another diamond. For this reason, diamond has a hardness of 10, which is the highest on the Mohs scale.

| Hardness | Mineral | Hardness rating |

|---|---|---|

| 1 | Talc | Talc is brittle under a fingernail. |

| 2 | Gypsum | Gypsum can be scratched by a fingernail. |

| 3 | Calcite | Calcite can be scratched by a copper coin. |

| 4 | Fluorite | Fluorite can be easily scratched by a knife. |

| 5 | Apatite | Apatite can be scratched by a knife. |

| 6 | Orthosis | Orthoclase can be scratched by a steel file. |

| 7 | Quartz | Quartz can be scratched by glass. |

| 8 | Topaz | Topaz can be scratched by tungsten carbide. |

| 9 | Corundum | Corundum can be scratched by silicon carbide. |

| 10 | Diamond | Diamond can be scratched by another diamond. |

Elasticity is the ability of a material to deform and then return to its original shape after undergoing deformation.

Several plastics and some composite materials have good elasticity.

After deformation, some materials can be restored to their initial shape by applying force. However, if this is not a spontaneous response of these materials, they are not considered elastic.

Polychloroprene, commonly called neoprene, is a good choice for a wetsuit. Its elasticity is useful since the suit stretches easily when worn. When it is worn, it adjusts to the wearer’s body and when it is removed, the polychloroprene suit returns to its initial shape.

Sergey Nivens, Shutterstock.com

Elasticity should not be confused with malleability and ductility. In fact, these last properties imply that the material can deform and then retain its new shape. A ductile or malleable material cannot be elastic, since it cannot return to its initial shape by itself.

Brittleness is the ability of a material to break when subjected to constraints.

Ceramics such as glass or porcelain are materials with high brittleness. When subjected to mechanical stress, ceramics crack or break before being deformed.

The brittleness of glass makes it a good choice for the door of this fire extinguisher and hose cabinet. In case of emergency, the glass can be broken to gain access to the contents of the cabinet.

Sanchai Khudpin, Shutterstock.com

Repetitive constraints on a material can increase its brittleness. The greater the force of the constraints, the less the material can withstand the repetitions. This is referred to as mechanical fatigue. For example, when a paper clip is unfolded and folded several times, it eventually breaks.

In general, materials that are brittle are neither ductile nor malleable, but they can be stiff.

Malleability is the ability of a material to deform without breaking and to retain its new shape. Thus, the material can be flattened, curved, or bent.

Most metals and alloys have good malleability. This is why these materials are frequently selected for food packaging and jewellery.

The malleability of aluminum allows it to be rolled into sheets. The aluminum foil is then folded to produce food containers.

Nordrodeb, Shutterstock.com

Gold is a metal used in jewellery for its great malleability. It can be given a wide variety of shapes.

Nice_Bryu, Shutterstock.com

To be malleable, the material must retain the new shape it has been given. For example, a crushed aluminum can will retain its new flattened shape. In contrast, a crushed sponge will return to its original shape. The sponge is not malleable, it is instead elastic.

Generally, materials that are malleable are also ductile.

Resilience is the ability of a material to withstand intense and sudden constraints.

Plastics and certain composite materials are examples of materials with great resilience. These materials tend to absorb the energy of an impact with little or no deformation. This is why they are excellent choices for protective equipment, sports equipment, and children's toys.

The resilience of fibreglass makes it a good choice for a motorcycle helmet. An arrangement of several layers of fibreglass protects the motorcyclist’s head from impacts.

Fox482, Shutterstock.com

Materials that have effective resilience are not brittle.

Stiffness is the ability of a material to resist deformation when subjected to constraints.

Materials with good stiffness are found in all types of objects. For example, walnut (wood), plexiglass (plastic), and plywood (composite material) are stiff. These materials retain their shape, that is, they do not bend, stretch, or curl. This makes these materials good choices for structures that support high loads such as buildings, houses, and bridges.

The stiffness of reinforced concrete makes this material a good choice for building a bridge. The bridge must withstand the constraints applied by the weight of the cars driving on it.

Randy Hergenrether, Shutterstock.com

The stiffness of wood makes it a good choice for framing a house. The wooden beams and joists support the weight of the floors, walls, and roof.

Den Rozhnovsky, Shutterstock.com

Generally, materials that are stiff are neither ductile nor malleable, but they can be brittle.

When designing a technical object, the overall function of the object must be considered, but also the factors that are likely to degrade over time. Being aware of the non-mechanical properties of materials helps guide an appropriate selection.

These non-mechanical properties can be either chemical or physical.

The following table displays the main non-mechanical properties of the materials.

| Property | Description | Examples of materials |

|---|---|---|

| Electrical conductivity | Ability to conduct electric current | Copper Gold |

| Thermal conductivity | Ability to transmit heat | Copper Cast iron |

| Lightness (low density) |

Characteristic of a material with low density | Carbon fibre Polystyrene (styrofoam) |

| Resistance to corrosion | Ability to resist the action of substances that cause corrosion (e.g. rust) | Stainless steel Plexiglass |

Electrical conductivity is the ability of a material to conduct electric current.

Metals and alloys are generally excellent electrical conductors. This means that electric current can easily flow through them.

Copper's high electrical conductivity makes it an excellent choice for conducting wires.

demarcomedia, Shutterstock.com

The measurement of the electrical conductivity of a material is carried out with an electrical conductivity detector (ECD).

Materials with low electrical conductivity are electrical insulators. Woods and ceramics are examples.

In general, materials that have good electrical conductivity also have good thermal conductivity.

Thermal conductivity is the ability of a material to conduct heat.

Metals and alloys have excellent thermal conductivity because they easily conduct heat.

Heat is transferred through a material by conduction. If one end of a material is heated, the heat transfer to the other end depends on the thermal conductivity. The higher it is, the faster and more effectively the material spreads the thermal energy initially provided.

The thermal conductivity of cast iron makes it a good choice for this hot plate. The plate transmits the heat to the crepe.

Irine and Andrew, Shutterstock.com

Ceramics have low thermal conductivity as they hardly transmit heat. They are thermal insulators.

In general, materials that have good thermal conductivity also have good electrical conductivity.

Lightness is a characteristic property of a material with low density.

Plastics and many composite materials are lightweight (low density). Sporting goods, children's toys, and even outdoor equipment are all examples where lightness is an asset, as it makes the objects easier to use and carry.

The lightness of carbon fibre makes it a good choice for this high-performance racing bike.

bestserk, Shutterstock.com

Resistance to corrosion is the ability to withstand the action of substances that cause corrosion (e.g. rust).

Oxygen, salts, and smoke are substances that can cause corrosion of a material. The presence of corrosion is unwanted since when it forms, it degrades the material and reduces the material’s properties. Over time, it can erode and tear through the material. The presence of water or moisture accelerates the corrosion of a material.

The metal of this boat propeller is degraded by corrosion.

MeSamong, Shutterstock.com

The use of plastic materials, composite materials, or certain alloys which have an effective resistance to corrosion is sensible for avoiding degradation of objects.

The resistance to corrosion of stainless steel makes it an excellent choice for this restaurant kitchen.